News Story

Understanding Heat Where It Matters Most

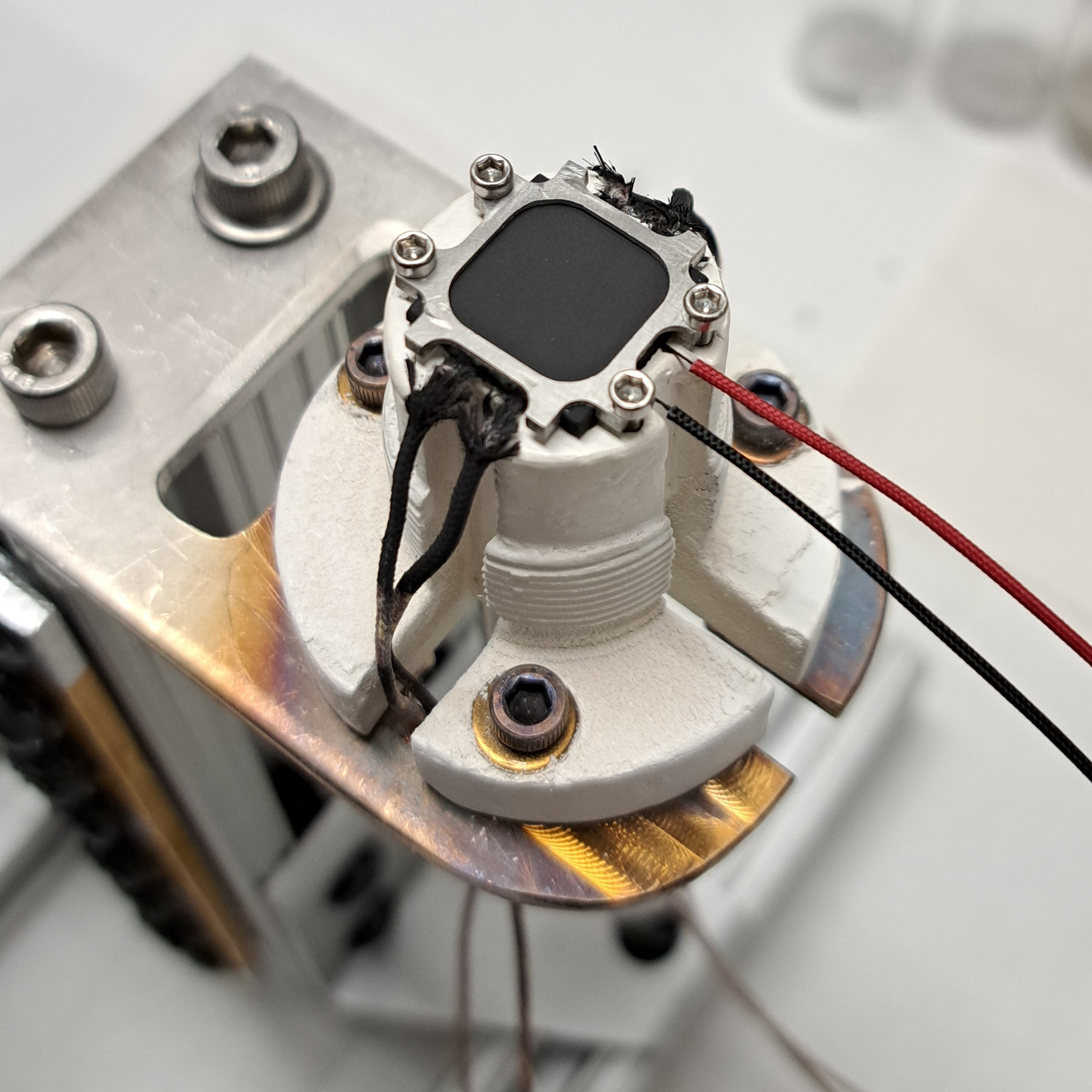

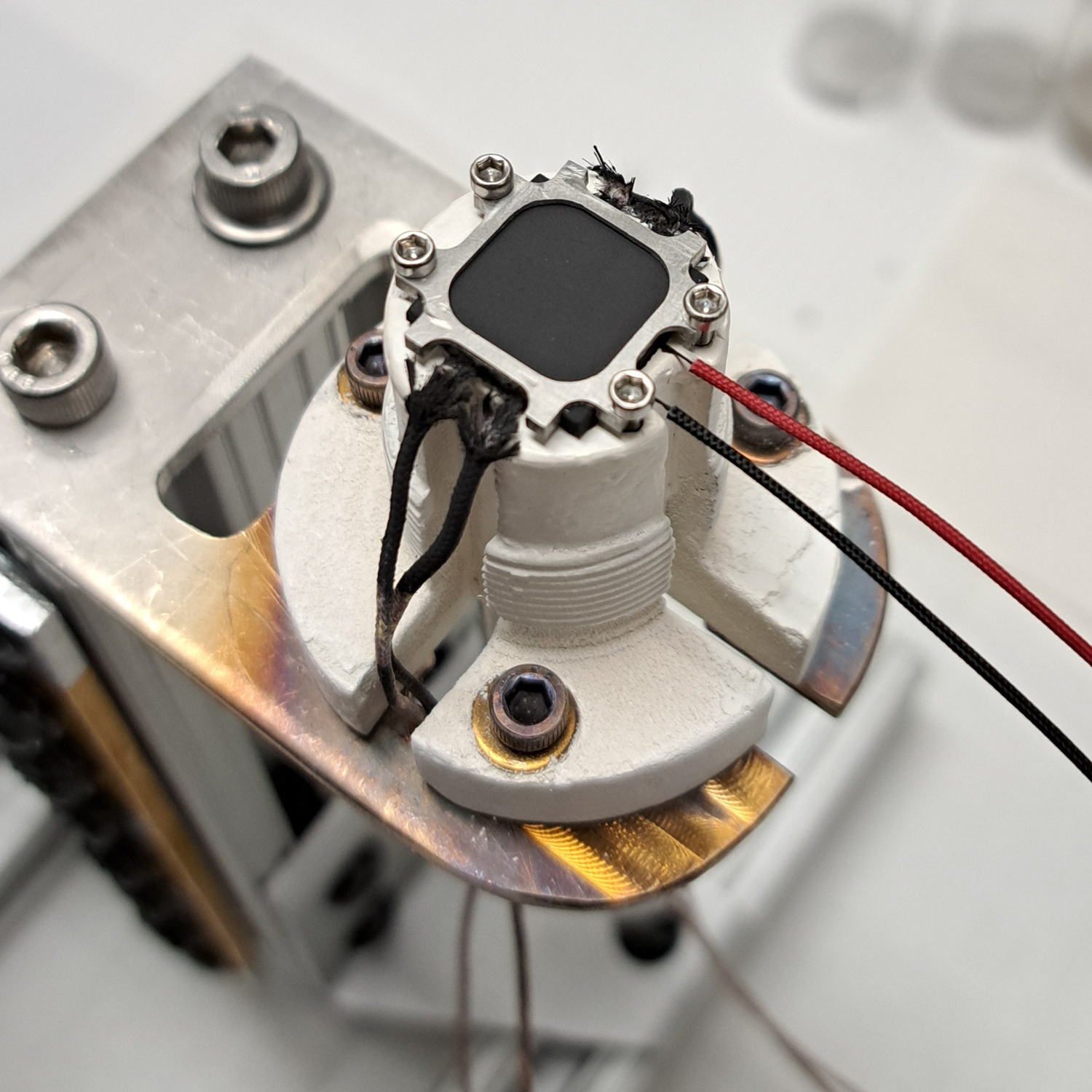

Exploded view of the team’s high-temperature transverse Seebeck effect (TSE) heat flux sensor. Their design requires very few components.

From advancing clean energy systems to improving next-generation aerospace technologies, a new heat flux sensor developed at the University of Maryland (UMD) could transform how engineers design for, and understand, extreme thermal environments. Built using rhenium and a unique simplified structure, the new sensor is capable of operating at temperatures up to, and likely beyond, 1000 °C.

The research by University of Maryland aerospace engineering Ph.D. student Kenneth McAfee was published in Sensors and Actuators Reports, and co-authored with faculty advisors Oded Rabin (associate professor, Materials Science and Engineering and IREAP) and Peter Sunderland (professor, Fire Protection Engineering).

|

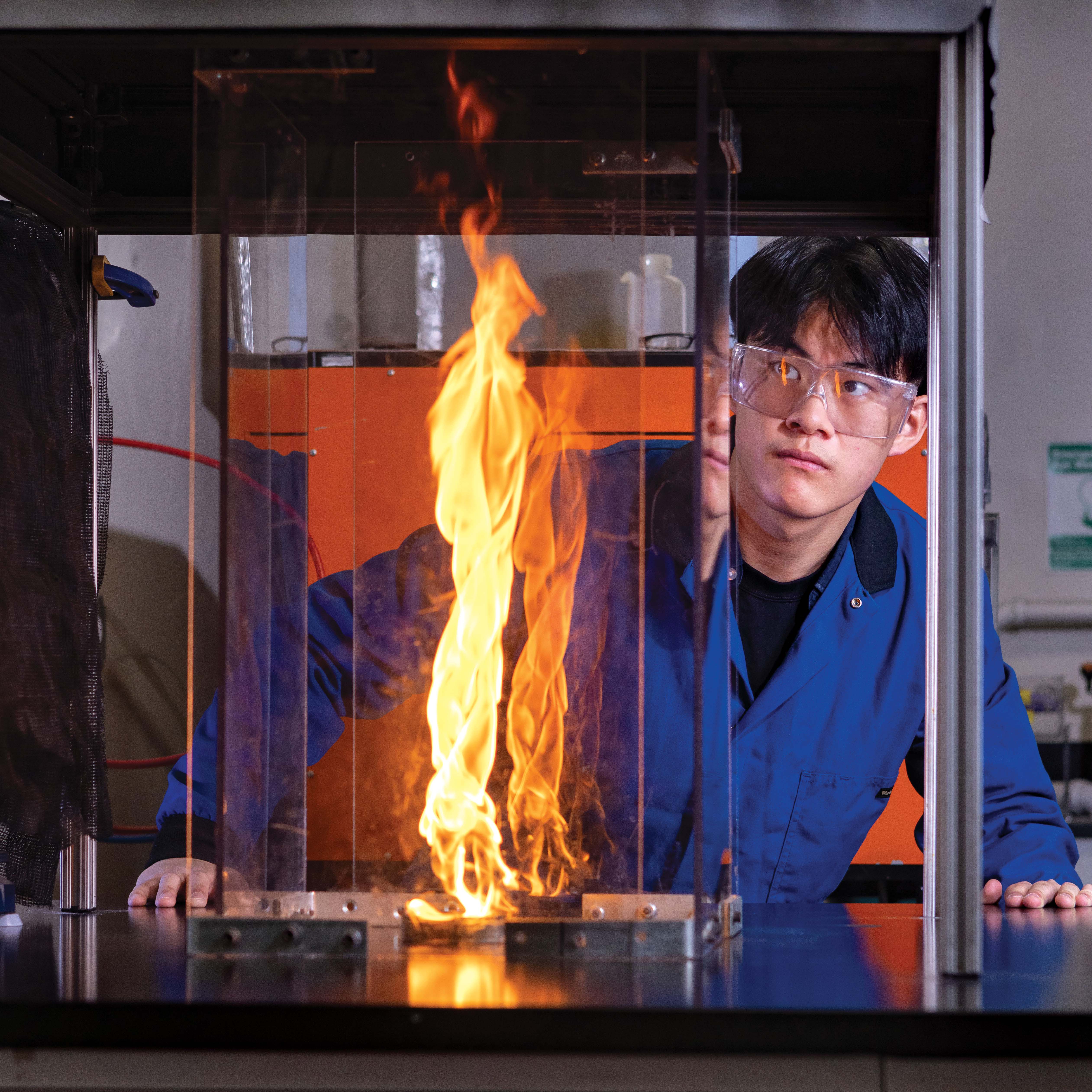

| The team's high-temperature TSE heat flux sensor mounted to a copper heat sink. The heat sink is spray-coated with boron nitride to inhibit oxidation. The heat sink has integrated coolant channels for water or air (not visible). |

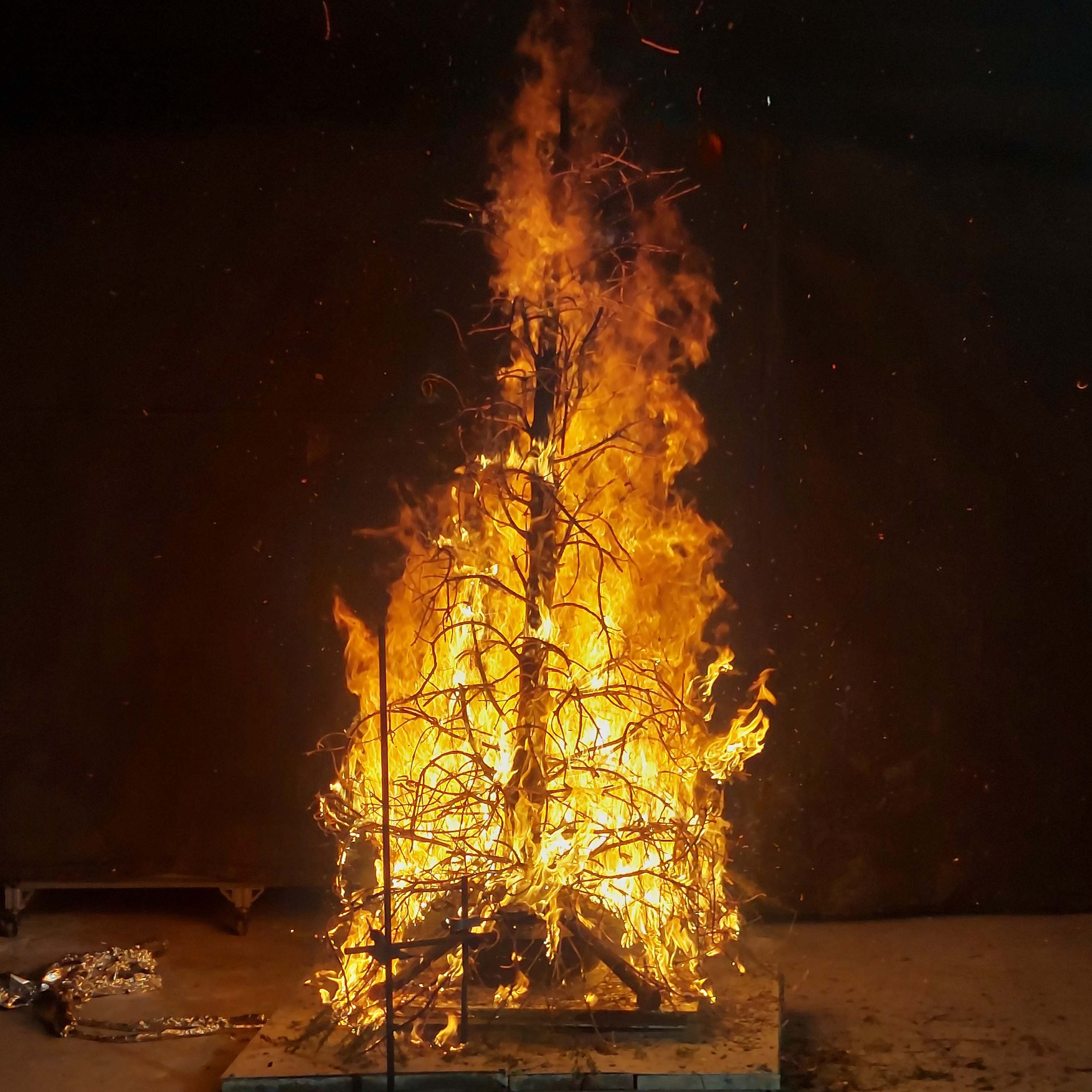

“This paper is really a culmination of about five years developing high-temperature heat flux sensors for extreme environment applications,” said McAfee, who successfully defended his thesis this fall, and was an Alex Brown Scholar in Aerospace Engineering. “The highlight here is how we used a lesser-known phenomenon called the transverse Seebeck effect (TSE) to build a sensor that works a little bit differently than conventional sensors—and to hopefully prove it out as a technology for high temperature applications.”

Heat flux, how much energy flows into a material per unit area, is a more useful measurement than temperature alone in predicting how a system will behave under extreme thermal conditions.

“Engineering systems fail because of temperature. Things get too hot and they break down,” explained McAfee. “But if you can predict the heat loads a material or structure is going to experience, you can reliably predict these temperatures and more thoroughly design the system.”

The sensor developed by McAfee and his collaborators is built around rhenium, a refractory metal with one of the highest known melting points and an anisotropic crystal structure—meaning its properties vary with its orientation.

“Rhenium has a very good resilience at high temperatures. Its melting point is in excess of 3000 °C,” said McAfee. “It also enables the transverse Seebeck effect, which is a unique behavior where a heat flux in one direction can create a voltage in a perpendicular direction.”

|

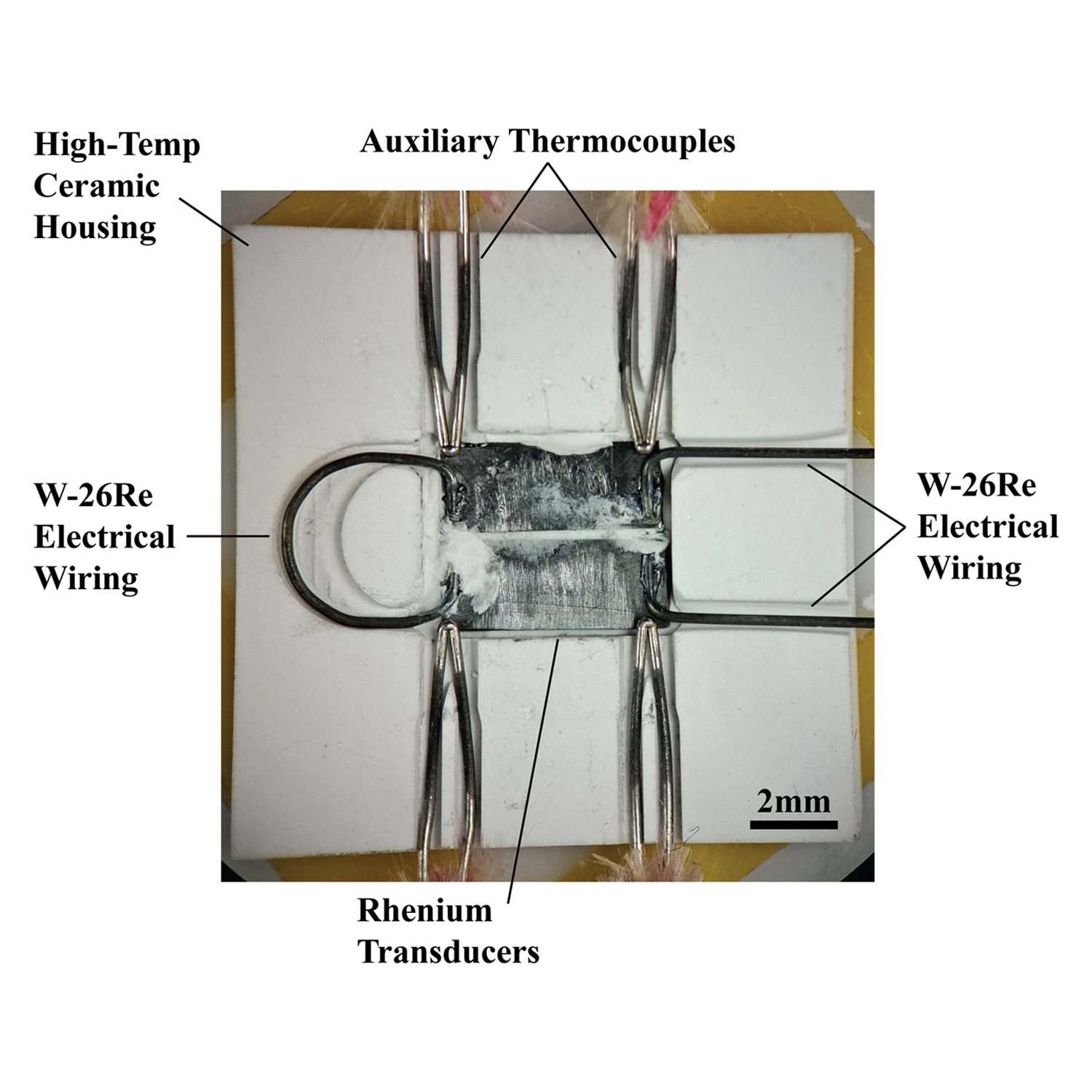

| Optical image of the back side of the TSE heat flux sensor during assembly, prior to sealing with cement. |

These unique properties allowed the team to design a sensor with a much simpler overall construction which means there are far fewer points of failure. “Compared with other high-temperature sensors in the literature, it has the simplest construction out of anything that exists,” said McAfee.

Another unique aspect of their sensor is that it gets more sensitive as temperatures rise, without reaching a plateau like most conventional thermoelectric devices.

“All the evidence we see indicates that the sensitivity keeps going up, even past 1000 °C, and that’s actually pretty unique to rhenium,” he said.

Funded by the U.S. Department of Energy, the team’s sensor was initially intended for applications in power plants, but could be extrapolated into other industries and uses.

“Traditional large-scale power plants were designed to operate under a very specific load that doesn’t really change,” McAfee explained. “But as we transition to alternative energy sources like solar, the loads on fossil fuel-burning plants have become a lot more dynamic and unpredictable. That makes them run less efficiently, and higher emissions are a result.”

Installing heat flux sensors in these facilities could enable real-time measurements of the heat output from the combustion of fuel, helping operators tune processes for greater efficiency. “If we can get a sensor that is as close as possible to the conversion from chemical fuel to heat, we can have a better understanding of how the power plant responds to dynamic conditions in real time,” he said.

The sensors also fill a critical diagnostic gap where optical thermal imaging fails. “In these power plant facilities, the exhaust is very dirty. So, you can’t see through it,” said McAfee. “But this [sensor] lets us get up close to the action.”

While the published work focuses on demonstrating the sensor platform, McAfee noted that future designs could push operating temperatures even higher by swapping out packaging materials or using advanced ceramic technology.

“Right now, our paper is really a demonstration of the platform for sensing,” he said. “But you can improve on this using different materials and different packaging. The only mandatory ingredient here is the rhenium.”

What makes the team’s sensor especially promising isn’t just its resilience, but its simplicity—fewer components, fewer failure points, and increasing sensitivity at higher temperatures. That, combined with rhenium’s unique properties, makes it an ideal candidate for widespread deployment in a variety of extreme environment applications.

Published November 11, 2025