Overview

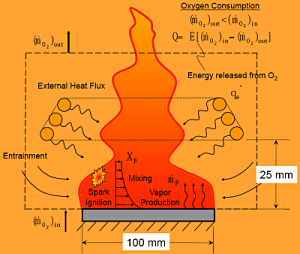

The ASTM E1354 standard for the cone calorimeter sets out to determine the response of materials exposed to controlled levels of radiant heating with or without an ignition source. The cone calorimeter became the premier dynamic research tool based on the principle of oxygen consumption calorimetry. Radiant heat is the major cause of fire spread and the cone measures intensity of the peak rate of heat release (PRHR) and the speed to reach PRHR; the critical factors in predicting the growth rate of fire.

The ASTM E1354 standard for the cone calorimeter sets out to determine the response of materials exposed to controlled levels of radiant heating with or without an ignition source. The cone calorimeter became the premier dynamic research tool based on the principle of oxygen consumption calorimetry. Radiant heat is the major cause of fire spread and the cone measures intensity of the peak rate of heat release (PRHR) and the speed to reach PRHR; the critical factors in predicting the growth rate of fire.

Various output data are collected including peak rate and average rate of heat release, total heat released, effective heat of combustion, specific extinction area, exhaust flow rate, mass loss rate and final sample mass, time to sustained ignition, O2, CO, CO2, and toxic gas concentrations, and smoke density as a function of time.

Setup

The test apparatus consists of the following components: a conical radiant electric heater; specimen holders; an exhaust gas system with oxygen monitoring and flow measuring instrumentation; an electric ignition spark plug; a data collection and analysis system; and a load cell for measuring specimen mass loss. A photo of the apparatus is shown below.

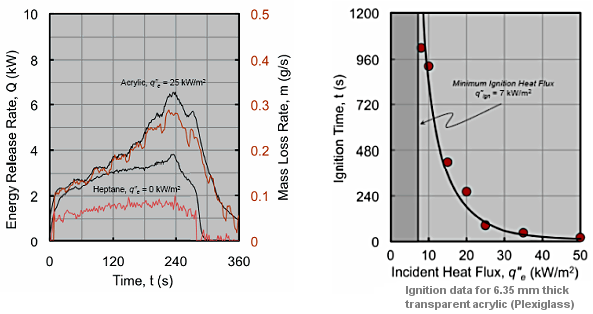

Analysis The ASTM E1354 test method has been developed for material evaluations, computer modeling, design purposes, and development and research to help make real world fire predictions. The test performance uses the bench-scale system to measure fire characteristics associated with heat and smoke output. The measurements can be used directly by researchers or can be used as data input into correlation or mathematical models used to predict fire development. Energy release rate data for Acrylic (6.35 mm thick) and Heptane (provided for reference). The measured heat of combustion for Heptane was 41.6 MJ/kg, comparing well with the literature [Δhc = 41.2 MJ/kg, 3rd Edition of SFPE Handbook]. The measured Δhc for Acrylic was 17.7 MJ/kg.

The ASTM E1354 test method has been developed for material evaluations, computer modeling, design purposes, and development and research to help make real world fire predictions. The test performance uses the bench-scale system to measure fire characteristics associated with heat and smoke output. The measurements can be used directly by researchers or can be used as data input into correlation or mathematical models used to predict fire development. Energy release rate data for Acrylic (6.35 mm thick) and Heptane (provided for reference). The measured heat of combustion for Heptane was 41.6 MJ/kg, comparing well with the literature [Δhc = 41.2 MJ/kg, 3rd Edition of SFPE Handbook]. The measured Δhc for Acrylic was 17.7 MJ/kg.

Top